FABRIC BUILDINGS

What is a Fabric Building?

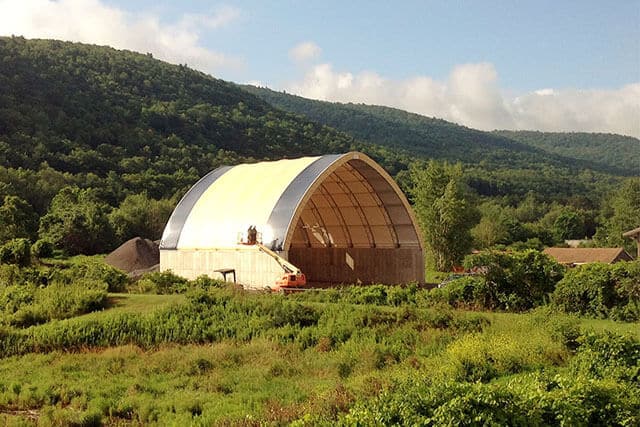

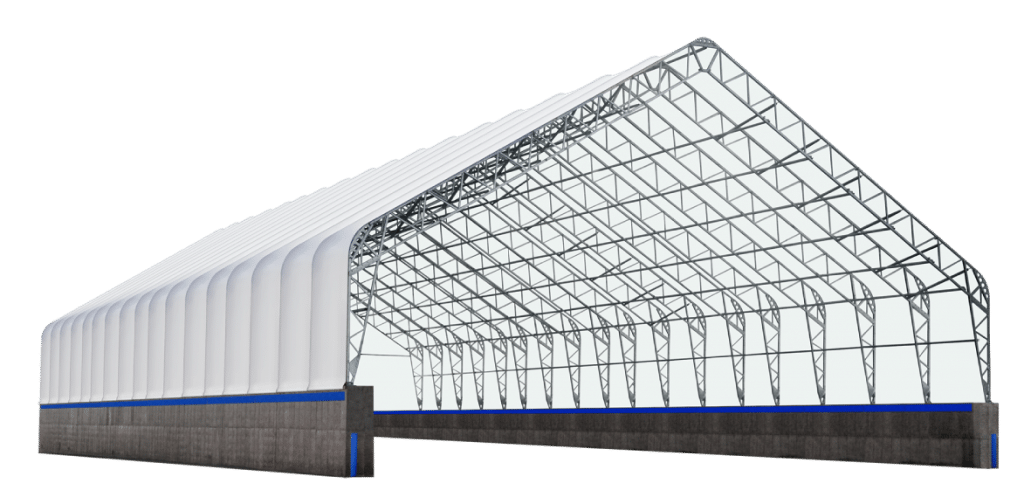

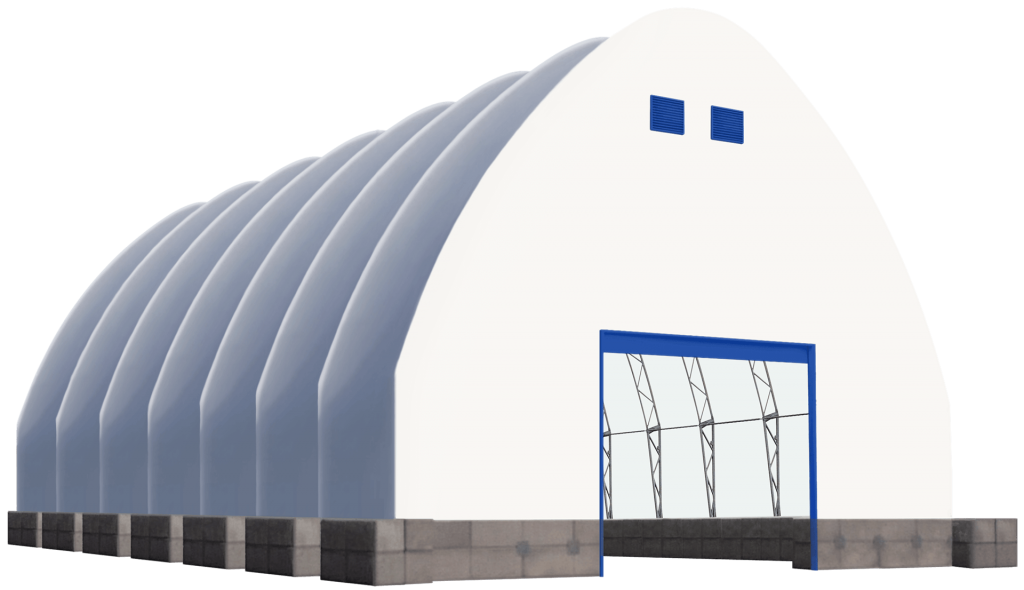

A fabric-covered building is a structure that includes a steel truss frame and a durable fabric covering. They can be either a permanent or temporary alternative to a traditional wood or steel structure. Offering several benefits, including quick installation, a bright and quiet interior, low maintenance needs, and exceptional durability, fabric buildings from Coverco are also affordable and offer a quick return on investment. The foundation, size, and design of the structure you need will vary based on your industry. In our experience, fabric buildings are the ideal solution for sand and salt storage facilities, oil and gas remote drilling sites, hay storage buildings, and more. We have over 20 years of experience in supplying and installing fabric structures in Alberta and Saskatchewan. Our focus on superior engineering and after-sales customer support is what sets us apart from other companies.

OUR VALUED CLIENTS

Cost Effective

Fabric buildings are more cost-effective and faster to install than a traditional building, which means a quicker and higher ROI.

Low Maintenance

Fabric buildings are low-maintenance structures compared to traditional buildings. Plus, at Coverco, we take care of all repairs.

Durable Design

The frames of our fabric buildings are made from hot-dipped galvanized steel which offers durable and reliable support.

Bright Interior

One of the most significant benefits of fabric buildings is that they offer a naturally bright, sunlit interior with a clear span frame.

Easily Relocatable

Our fabric buildings entail a quick and easy installation process which means they can be easily relocated in the future.

50-Year Warranty

Coverco Buildings offers the best warranty in the business with a 50-year protection plan in addition to the standard warranty.

Cost Effective

Fabric buildings are much more cost-effective and faster to install than a traditional building, which means a quicker and higher ROI.

Low Maintenance

Fabric buildings are low-maintenance structures compared to traditional buildings. Plus, at Coverco, we take care of all repairs.

Durable Design

The frames of our fabric buildings are made from hot-dipped galvanized steel which offers durable and reliable support.

Bright Interior

One of the most significant benefits of fabric buildings is that they offer a naturally bright, sunlit interior with a clear span frame.

Easily Relocatable

Our fabric buildings entail a quick and easy installation process which means they can be easily relocated in the future.

50-Year Warranty

Coverco Buildings offers the best warranty in the business with a 50-year protection plan in addition to the standard warranty.

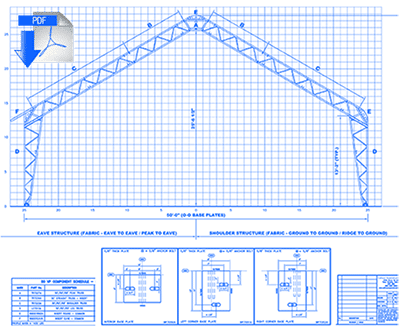

VP SERIES

Width: 30′ to over 250′

Length: Unlimited

Versatile Product

This versatile design allows for interchangeable trusses, enabling buildings of any dimension and accommodating a wide variety of applications. The VP series is engineered to suit specific client needs and is completely customizable. Wood or steel finishing provides a traditional, polished look.

STANDARD FEATURES

- Hot dipped galvanized steel frame

- Stainless steel cables

- Hot dipped galvanized hardware

- 12 oz high density polyethylene fabric

- Individual fabric section panel system

OPTIONS

- Steel legs with different height options 8′ & 14′

- 4′ eaves for a conventional structure profile

- Roof vent support systems

- PVC available upon request

- Choice of fabric or steel end walls/side walls

VP PROFILES

50′ VP Profile Eave – Round Shoulder

60′ VP Profile Eave – Round Shoulder

65′ VP Profile Eave – Round Shoulder

65′ VP Profile Upgrade – Eave – Round Shoulder

70′ VP Profile Eave – Round Shoulder

80′ VP Profile Eave – Round Shoulder

90′ VP Profile Eave – Round Shoulder

100′ VP Profile Eave – Round Shoulder

100′ VP Profile Upgrade – Eave – Round Shoulder

110′ VP Profile Eave – Round Shoulder

120′ VP Profile Eave – Round Shoulder

140′ VP Profile Eave – Round Shoulder

150′ VP Profile Eave – Round Shoulder

160′ VP Profile

*Larger dimensions available upon request

Need help or customization?

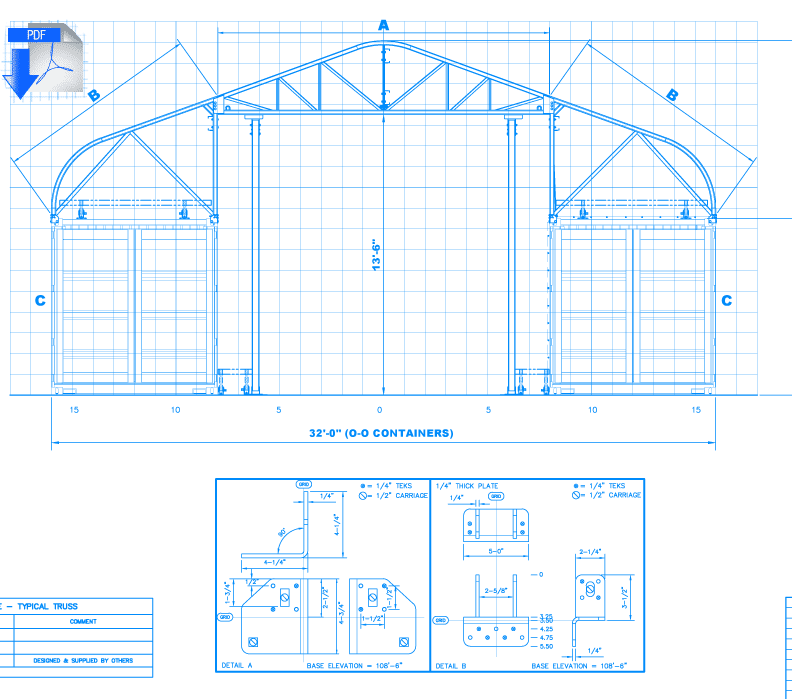

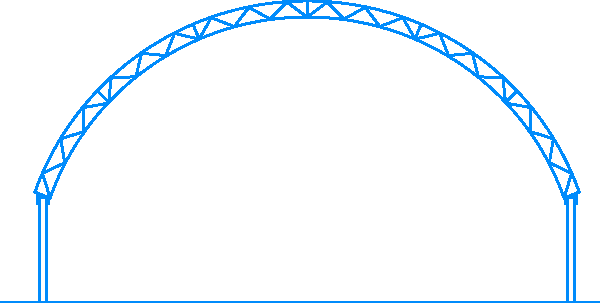

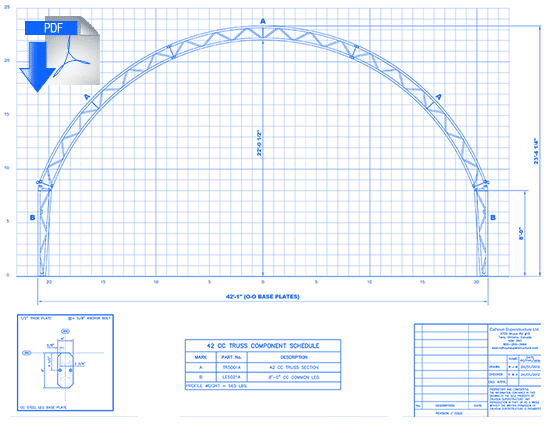

CC SERIES

Width: 32′ 42′ 52′ 62′ 72’ 82’

Length: Unlimited

Compression Coupler

This unique design implements a coupler and gusset combination which permits a dispersed transfer of pressure over the connecting cords. This superior engineering solution achieves greater design capacity over competitor flat plate gusset design which transfers pressure entirely to the end of the tube. The CC series is completely customizable to suit a wide variety of applications. Finished in wood or steel siding can provide a traditional look.

STANDARD FEATURES

- Hot dipped galvanized steel frame

- Stainless steel cables

- Hot dipped galvanized hardware

- 12 oz high-density polyethylene fabric

- Individual fabric section panel system

OPTIONS

- Engineered wood post

- Steel legs – Heights: 2’ 4’ 6’ 8’ & 10’

- 4’ eave bunker covers

- Roof vent support systems

- Individual fabric section panel system

- PVC available upon request

- Choice of fabric or steel end walls/side walls

CC PROFILES

32′ CC 2′ Steel Leg Profile

32′ CC 4′ Steel Leg Profile

32′ CC 6′ Steel Leg Profile

32′ CC 8′ Steel Leg Profile

32′ CC Concrete Profile

32′ CC Wood Post Profile

42′ CC 2′ Steel Leg Profile

42′ CC 4′ Steel Leg Profile

42′ CC 6′ Steel Leg Profile

42′ CC 8′ Steel Leg Profile

42′ CC Concrete Profile

42′ CC Wood Post Profile

52′ CC 2′ Steel Leg Profile

52′ CC 4′ Steel Leg Profile

52′ CC 6′ Steel Leg Profile

52′ CC 8′ Steel Leg Profile

52′ CC Concrete Profile

52′ CC Wood Post Profile

62′ CC 2′ Steel Leg Profile

62′ CC 4′ Steel Leg Profile

62′ CC 6′ Steel Leg Profile

62′ CC 8′ Steel Leg Profile

62′ CC Concrete Profile

62′ CC Wood Post Profile

*Larger dimensions available upon request

Need help?

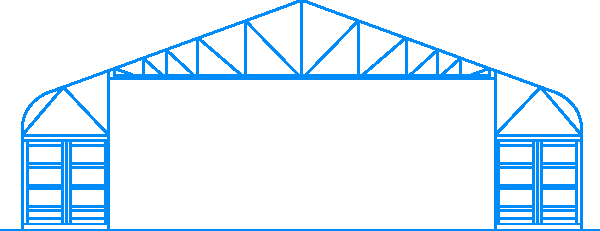

CL /ST SERIES

Width: 16′ 20’ 24’ 30′ & 36’

Length: Unlimited

Portable

The Container Line Building Series is the first-ever fabric structures building in the industry that has been designed and engineered exclusively for container-use only. The CL Building Series is engineered site-specific to suit any location in North America, and can be used as either a temporary or permanent solution for anything from hay storage to salt storage.

STANDARD FEATURES

- Hot dip galvanized brackets/base plates

- Hot dipped galvanized hardware

- No Steel Welding

- 7 oz high-density polyethylene fabric

OPTIONS

- 12 oz high-density polyethylene fabric

- Steel legs with different height options

CL / ST PROFILES

Need help?

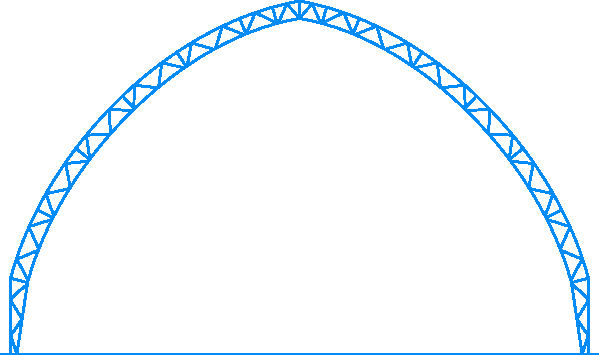

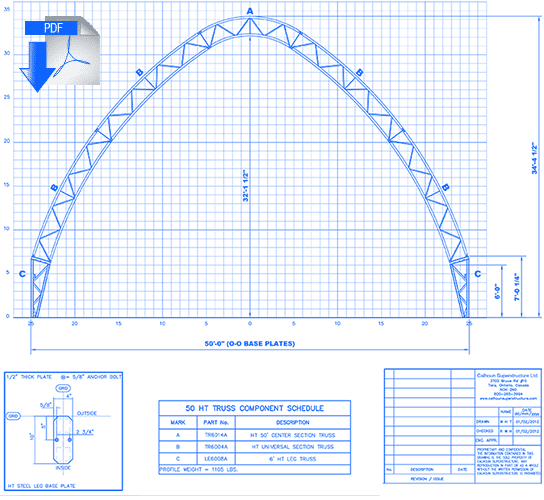

HT SERIES

Width: 35’ 60’ 65’ 72’ & 82’

Length: Unlimited

High Top

This series utilizes the same unique compression coupler design as the CC series, but implements larger top and bottom cords with a deeper truss depth. This structure is ideally suitable for extra interior height requirements. The clear span space accommodates unloading of large trucks and the high-arching roofline is able to endure heavy snow loads. The HT series is completely customizable to suit a wide variety of applications. Finished in wood or steel siding can provide a traditional look.

STANDARD FEATURES

- Hot dipped galvanized steel frame

- Stainless steel cables

- Hot dipped galvanized hardware

- 12 oz high-density polyethylene fabric

- Individual fabric section panel system

OPTIONS

- Steel legs – Heights: 2’ 4’ 6’ 8’ & 10’

- 4’ eave bunker covers

- Roof vent support systems

- PVC available upon request

- Choice of fabric or steel end walls/side walls

HT PROFILES

50′ HT 2′ Steel Leg Profile

50′ HT 4′ Steel Leg Profile

50′ HT 6′ Steel Leg Profile

50′ HT 8′ Steel Leg Profile

50′ HT Concrete Profile

60′ HT 2′ Steel Leg Profile

60′ HT 4′ Steel Leg Profile

60′ HT 6′ Steel Leg Profile

60′ HT 8′ Steel Leg Profile

60′ HT Concrete Profile

65′ HT 2′ Steel Leg Profile

65′ HT 4′ Steel Leg Profile

65′ HT 6′ Steel Leg Profile

65′ HT 8′ Steel Leg Profile

65′ HT Concrete Profile

72′ HT 2′ Steel Leg Profile

72′ HT 4′ Steel Leg Profile

72′ HT 6′ Steel Leg Profile

72′ HT 8′ Steel Leg Profile

72′ HT Concrete Profile

82′ HT 2′ Steel Leg Profile

82′ HT 4′ Steel Leg Profile

82′ HT 6′ Steel Leg Profile

82′ HT 8′ Steel Leg Profile

82′ HT Concrete Profile

*Larger dimensions available upon request

Need help?

Fabric Buildings Built For Canada's Climate

Our superior products are specifically engineered with Canada’s harsh climate in mind. We design each building to ensure consistent quality, capable of withstanding the uniquely harsh and rugged local climate and elemental stresses of the Canadian prairies. We supply fabric buildings for anything from an indoor volleyball or tennis court to a temperature-controlled coverall barn. We customize your structure’s foundation, HVAC and electrical system, insulation, and flooring to meet your unique needs. At Coverco Buildings, we also offer the best warranty in the business with a 50-year protection plan. We guarantee quality and assure the longevity of fabric buildings in Alberta and Saskatchewan. No one does fabric buildings better than us.

OUR BUILDINGS ARE IDEAL FOR

Sand/Salt

Oil & Gas

Warehouse & Equipment Storage

Agriculture & Equestrian

Mining

Sports & Recreation

Waste Recycling & Compost

Fertilizer

Like sand and salt, fertilizer is also a corrosive material and requires specific conditions when it comes to long-term storage. Our hot-dip galvanized steel frames and structures can withstand rust and deterioration, unlike most other metals. We can customize your building with added protection for a safe and secure fertilizer storage facility.

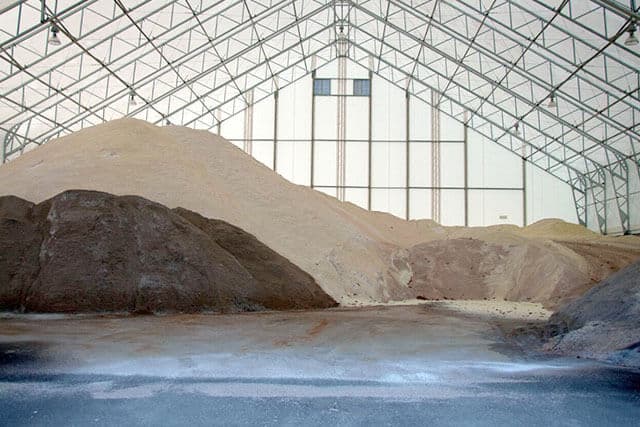

Sand / Salt

Sand and salt storage is one of the most common uses for our industrial fabric covered buildings. We cater to municipalities that require a storage solution for the uniquely corrosive properties of salt and sand. Our structures are durable and practical; offering added protection against rust and deterioration.

Oil & Gas

Our structures are of the highest industrial quality and can be customized or expanded to meet the needs of the oil and gas industry. They are easy to relocate and install in remote drilling locations. Whether you need a permanent or temporary solution for a drilling site, processing facility, or storage, Coverco can help.

Warehouse & Equipment Storage

Our fabric and steel structures are extremely versatile and durable. We can evaluate your needs for storing equipment and machinery, finished products, or raw materials, and provide a building solution that is the right shape and size. Our steel buildings can also accommodate offices and workspaces to meet your needs.

Agriculture & Equestrian

In the agriculture industry, custom engineering is required to provide a structure that offers a safe and ideal solution for anything from hay and equipment storage to livestock housing and equestrian tracks. Our fabric buildings are spacious and bright, simulating the airiness of the outdoors while providing the comfort of indoor temperatures and protection from the elements.

Mining

Our buildings come in several shapes and sizes and are easy to relocate and install in remote areas. For this reason, Coverco fabric buildings are ideal for the mining industry, whether you require a temporary or permanent building. Our fabric structures are versatile when it comes to style and foundation type; they can stand wherever your drilling operations occur.

Sports & Recreation

Experience the versatility of our fabric and steel buildings. As a sports facility, our buildings can accommodate anything from an indoor ice rink, tennis court, or soccer field, to a driving range or paintball grounds. As a general recreation facility, the sky’s the limit. A durable, multi-purpose, fabric building facility can house weddings, conventions, trade shows, markets, concerts, and more.

Waste, Recycling & Compost

Our custom engineered buildings with clear span interiors offer maximum functionality for the waste and recycling industry. Select features include odour-control, durability, and brightly-lit interiors. Our structures can make handling, sorting, and storing waste, recyclables, and compost materials easy and economical, not to mention safe.

Why Coverco

Qualified Professionals

At Coverco, you have the opportunity to work with a trained team of professionals. With decades of experience, we adhere to industry standards to ensure safety and quality are the priority.

Sophisticated Solutions

We only work with the best manufacturers in the country to provide turnkey solutions for fabric covered and steel buildings. Our dedication to structural integrity helps us stand out from the rest.

Full Project Management

We offer full project management to ensure your project stays on track, and you are kept up to date with any changes. We also foster open lines of communication with our clients.

Exceptional Execution

Because we are a solution-driven company, we aren't satisfied until the execution of every project is flawless and our clients are satisfied. We ensure a smooth and easy process.

Start Working With the Best

Durable Fabric Covered Buildings in Alberta & Saskatchewan

How do we ensure superior engineering? At Coverco Buildings, it’s the foundation of everything we do. Our fabric structures offer almost the same strength and durability as our pre-engineered steel buildings. The high-density fabric and hot-dip galvanized steel trusses offer more than meets the eye. All structural frames and other critical components undergo the galvanization process. This process occurs after fabrication, resulting in full and comprehensive coverage, inside and out, including welds. The hot-dip galvanization process creates a metallurgical bond between the steel and zinc-iron alloys. The result is a protective coating harder than the base steel with up to 4 times the amount of zinc protection than that of an in-line galvanized product. Select a concrete block, pier, slab, or wall foundation for a permanent, durable, and cost-effective building solution and experience all the benefits of a fabric coverall building from Coverco.

Process

The Hot Dip Galvanization Process

The hot-dipped galvanization process is how we ensure our steel frames last longer and are able to withstand any environment. The process involves bonding zinc to steel to create a stronger and more reliable material. Studies show that hot-dip galvanizing is one of the best ways to protect against rust, corrosion, and deterioration. The HDG process also makes for a smooth surface that won’t snag the fabric cover.

1

Surface Preparation

Surface preparation is extremely important; if not done correctly, the zinc will not adhere to the steel and sections will be left uncoated. Our steel undergoes three stages of preparation.

2

Caustic Cleaning

We use a hot alkali solution to remove organic contaminants, such as dirt, paint, grease, and oil. Epoxies, vinyl, asphalt, or welding slag removal occurs through grit or sandblasting.

3

Acid Pickling

All scaling and rust must be removed from the steel surface before galvanizing. We do this through pickling in a dilute solution of hot sulphuric acid or ambient temperature hydrochloric acid.

4

Flux Solution

Fluxing removes oxides and prevents further oxidation of the metal prior to galvanizing. The steel is dipped into an aqueous solution of zinc ammonium chloride and then fully dried.

5

Galvanizing

Each welded truss is immersed in a bath of 98% pure molten zinc at a temperature of about 840°F (449°C). The zinc metal reacts with the iron on the steel surface to form a zinc/iron intermetallic alloy.

6

Inspection

Following complete immersion, the trusses are withdrawn slowly from the galvanizing bath, and the excess zinc is drained off the surface. A unique vibrating technique is used to dry the metal.

7

Drying

After the trusses have dried, the thickness and appearance are closely scrutinized. Several different tests are used to determine thickness uniformity, adherence and overall appearance.