Benefits of Portable Fabric Buildings

When it comes to the design of your building, it’s important to consider how you intend to use it and whether its location will be

Blog

When it comes to the design of your building, it’s important to consider how you intend to use it and whether its location will be

When you invest in a new build, you likely want your building to stand the test of time. Having to spend more money a few

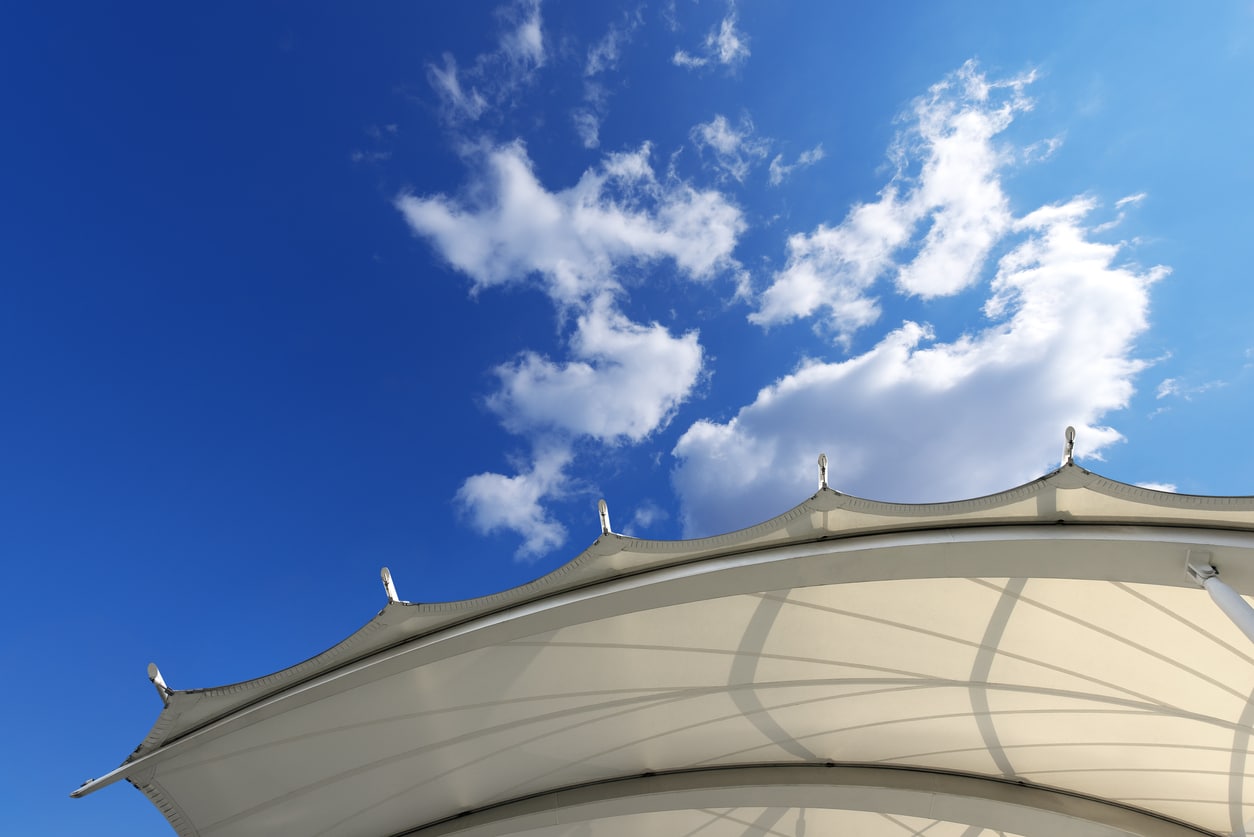

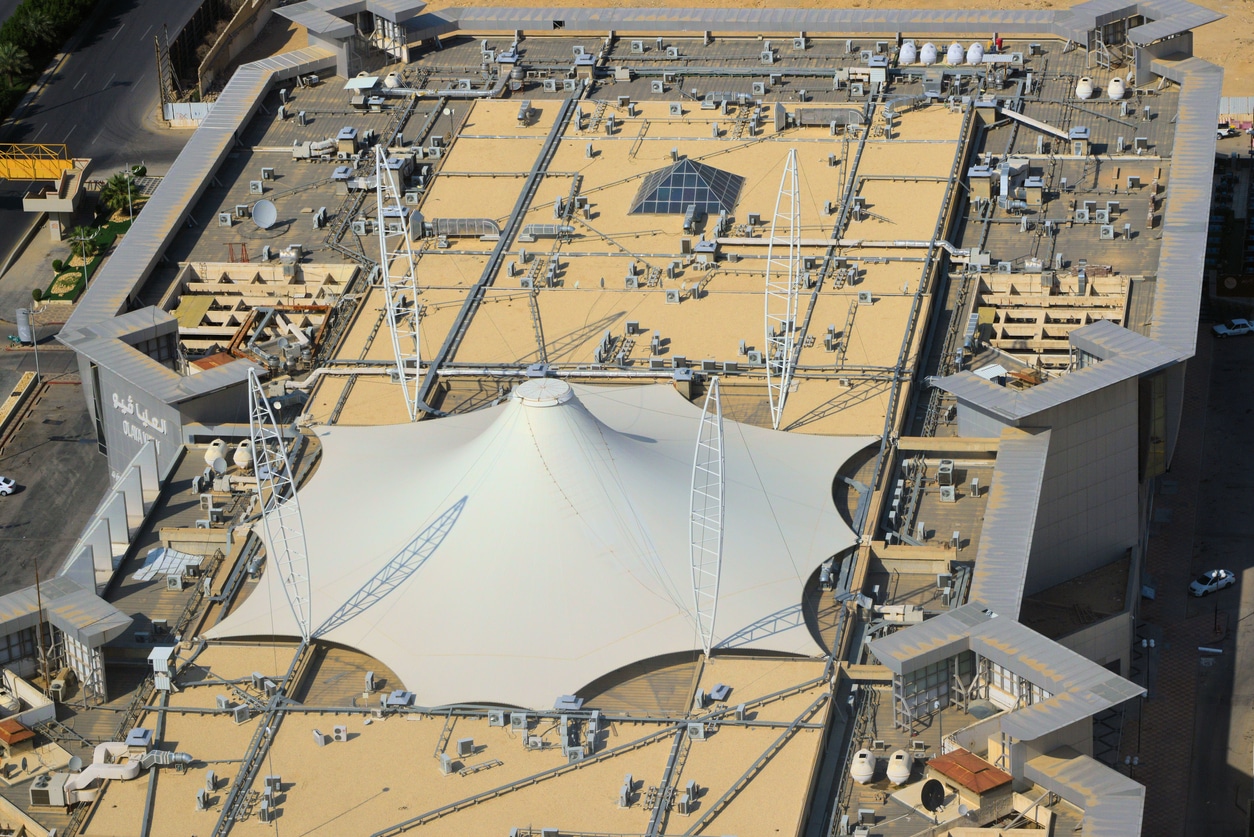

Choosing a fabric-covered building for your commercial construction may seem a little unconventional. However, it may actually be the smart decision when you consider how

So you’re looking to construct a building for residential or commercial use. There are many options you can go with as far as the material

If you need a temporary building for your next project, one type of building you should consider are fabric made buildings. These buildings have become

Are you thinking about insulating a steel building? Many people opt to go without insulation because they see it as an unnecessary expense. However, insulating

When you need to get more space quickly, then opting for pre engineered metal buildings is a smart choice. These buildings are very sturdy, and

There are many advantages to fabric buildings, such as their excellent weather resistance, convenient storage capabilities and easy-to-install design. In fact, they are the ideal

For steel buildings, insulation is a must. If you think of the benefits, you can see why investing in proper insulation can go a

There is a lot to learn about the different types of buildings available and the multiple solutions they can provide. However, today you can learn

© 2022 COVERCO BUILDINGS | TERMS